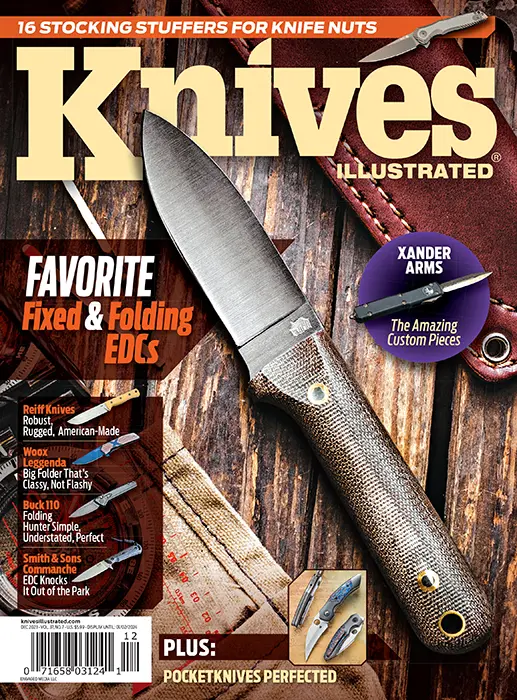

Plus, some custom knife makers you’ll definitely want to check out.

By: Jonathan Kilburn

Custom knife makers create several different products. The term “custom” itself would imply an individual can have any design they want made. While this is true with some makers, it’s not always a possibility. We’ll help you navigate the options and find the knife and knife maker that suits you.

First, Let’s Define “Custom”

For clarity’s sake, it would be better to say “handmade” instead, but custom is the term you hear most often. There are different kinds of custom knives out there, and they fall into four general categories.

Category #1: Unique, non-modified designs by the maker

These unique knives are one-of-a-kind. Designs may be similar among individual knives, but each knife is completely handmade. No two are alike. Parts for these knives aren’t interchangeable, and even a sheath is custommade. Makers like Jared Oeser, Nick Rossi, and Melvin Lozada all focus on their particular styles and do not deviate to suit individual customer preferences.

Jared Oeser started his career making full-tang, bushcraft-style blades. Now, he focuses on exceptional-quality folding knives with a superior fit and finish. They are small, practical, and super well-finished. Knives of this quality tend to appreciate as time goes on.

Nick Rossi, by contrast, makes knives in a broad range of styles: hybrid kitchen, hunting, and tactical. Each blade Rossi designs is meant for use and comes in a varied range of steels. From time to time, he will take on a custom knife project and manufacture a knife from his own lineup to his own specifications.

In Melvin Lozada’s designs, fantasy meets reality in exciting and crazy ways. Mixing a unique finish, Lozada offers a range of designs that aren’t matched by any other maker in this list. While designed with practicality in mind, it’s hard to pinpoint exactly what purpose each knife has. They all look great and perform every task perfectly.

There is not just one design that fits every kitchen task. With his experience as a bladesmith instructor in Maine, Nick Rossi has forged a unique balance in his kitchen knife lineup. No two are the same and each one he builds is meant to be used thoroughly.

Category #2: Knives based on a designer’s standard theme

Many makers focus on a specific style or blade. Some derive inspiration from styles from around the world. They often cultivate building techniques for these hard-to-manufacture blades. Hamidashi, Finnish puukko, and various Scandinavian grinds are difficult to perfect. These makers have devoted years to achieve that perfection.

With modification, you may be limited to blade length, steel choices, and handle designs. If searching for a particular style, this type of maker is the way to go. Not only will the result be a great blade, but the years of practice at a particular blade grind nearly guarantees perfection.

WoodBear Knives is a leading example of this kind of custom knife option. He includes a lineup of ready-made knives that will fit the mold for many interested in Scandinavian-grind blades. He will customize handle materials and blade length.

Anton Salnikov of Siberian Forge Knives also accomplishes this classic simplicity. His traditional Yakutian and Batiya knife designs have a history going back almost 1,000 years. These blades resemble bone knives and are easy to use, sharpen, and maintain. Anton can customize the blade length, handle length and all materials within his specific style. His personal history and connection are with the Yakut style, which shows through his designs.

Tera Forge Knives is another great example. They focus on puukko-style blades. Like the Yakut knives, puukko knives have a deep history that not many other styles compete with. The grind is closely related to Scandinavian-grind blades. (They both originate in Nordic countries.) The design is used for woodworking, fishing, and hunting, puukko knives were even used as bayonets during the Winter War. While handles, blade style, and lengths can be slightly modified — as is common with traditional puukkos — Tera Forge’s designs are classic and useful with eye-popping results.

Category #3: One-of-a-kind creations designed with customer input

When it comes to designing a blade that defines your unique style, these makers are the best choice. Completely custom makers like this represent a rare breed. They push the limits of their abilities in all directions. Handing them a drawing, soliciting their opinions, and working collaboratively to create your dream knife is what these makers are all about. Where they shine is in the ability to combine suitable steel, materials, and length for the design purpose. For this option, look for a maker who has had previous experience developing something close to what you want.

One maker that stands out in this highly competitive category of knife making is Jeremy Valentine of Valavian Edge Craft. Jeremy aims to produce both complicated and stylish designs. While he won’t construct just any design, all of his work is incredibly versatile, useful and completely functional. As Jeremy says, “No knife is useful if it doesn’t function.” Valavian Edge Craft has made an excellent reputation in the custom knife world and has built that reputation on the quality they produce.

Navarrete Knives also stands out against the pack as an innovative builder that challenges his own personal growth in knife design. Josh Navarrete is extremely involved in every aspect of his customer’s design and adds input along the way. Ultimately, it comes down to what’s requested, and he excels at bringing that creation into reality. No matter the style, it’s within his wheelhouse.

Josh Navarrete does not do simple. This walnut burl and African ebony bolster are situated on either side of an Amboyna burl belt and all put together with maple liners. Made from CPM3V this knife is a unique design for a customer. There is not another knife in the world like it.

Category #4: Somewhere in between

Halfway between the “theme” and “completely custom” categories lies Mike Jeffries of 2Birds Metalworks. He sits in a class by himself because he does some custom work, but generally will only modify his own unique style. With a mix between outdoor fixed blades and kitchen knives, there’s a lot that he has to offer. The type of work and complexity involved puts his knives in a league of their own.

Questions to ask

When shopping for a custom knife, you need to know what you need, before you know what to ask the knife maker for. Here are some questions to ask yourself before getting started.

Ask first: Why do you want a custom knife?

There are many mass-produced knives on the market that fulfill nearly every need, so why do you want a custom knife? It may be a desire for a limited steel availability in an existing design, or the need for a hybrid design. Or, it may be because of a disability. Some veterans find it incredibly difficult to find knives that they can efficiently use after having lost fingers, hands or arms. This is where a custom knife maker who is willing to drastically modify a design becomes a valuable resource.

Then ask: What knife style do you want?

Because many makers like to focus on a certain style, design or grind, they are going to be the best option for modifying a handle shape or blade length. If it’s a traditional design you want, it may be best to seek a designer who focuses on that. If one is not available, utilizing a completely custom maker to help throughout the process remains a perfectly reasonable option.

Next ask: What materials do you prefer?

Preferences are merely that. And this is one of the leading reasons people have custom knives made, as opposed to buying mass-produced blades that do not meet their preferences.

Siberian Forged Knives has one of the best standard sheaths the author has seen. It would be hard to find an alternative with a comparable type of museum quality design. (Photo by Jonathan Kilburn)

Another question: What is the production status?

This is more a question for the maker than the consumer. It’s critical to obtain the status on the production and listen to the maker’s remarks. If they are finding difficulties in a certain area of your design, don’t hold it against them. They recognize the limits of the materials and can offer suggestions along the way.

If you’re still set on a design, even if it’s not truly functional, communicate that to the maker. Staying in touch and expressing your expectations will allow a maker to truly customize your design to the best of his ability.

Finally: Is there a warranty?

A reputable maker will offer some type of warranty to cover workmanship. If they don’t offer a warranty, stay away.

Who is YOUR favorite custom knife maker? Let us know in the comments!

Subscribe / Back Issues

Subscribe / Back Issues